Date:2024-09-19 Categories:Product knowledge Hits:850 From: Guangdong Youfeng Microelectronics Co., Ltd(YFW)

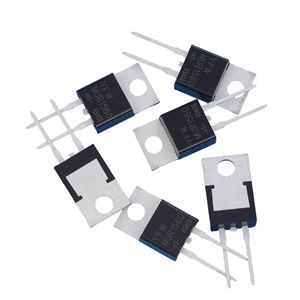

Fast recovery diode is a special type of diode designed to provide fast switching functionality in circuits, especially in high-frequency power supply and converter applications. So, what should be noted in circuit applications?

The basic principle of fast recovery diode

Fast recovery diodes can quickly recover from a conducting state to a cutoff state, which mainly depends on their internal structural design, enabling them to reduce power loss and improve efficiency when dealing with high-frequency signals. Compared with ordinary rectifier diodes, fast recovery diodes have significant improvements in reverse recovery time (trr).

Conventional inspection methods

1. Appearance inspection

Check the appearance of the diode: look for any physical damage, signs of burning, or signs of overheating. These may be preliminary signs of internal damage.

2. Positive pressure drop test

Using a digital multimeter: Set the multimeter to diode mode and measure the forward voltage drop of the diode. For fast recovery diodes, the forward voltage drop is usually between 0.6V and 1V, depending on the type of diode and the manufacturer's specifications.

3. Reverse recovery time test

Specialized instruments: The testing of reverse recovery time requires the use of an oscilloscope and specific testing circuits. This test is relatively complex and is usually conducted during the design validation phase or fault analysis, rather than conventional rapid inspection methods.

4. Reverse leakage current test

Using a digital multimeter: Measure the leakage current when the diode is in reverse direction in either diode or resistor mode. A good fast recovery diode should display very small leakage current or "OL" under reverse bias.

matters needing attention

The influence of temperature: When conducting tests, it is necessary to pay attention to the temperature of the diode. The performance of diodes, including forward voltage drop and reverse leakage current, will vary with temperature. Therefore, the temperature under testing conditions should be as close as possible to the temperature in the actual working environment of the diode.

The impact of testing circuits: When measuring reverse recovery time, the design of the testing circuit has a significant impact on the results. Ensure the use of appropriate loads and driving conditions to avoid misleading results due to improper testing circuit design.

Specification comparison: When conducting any testing on fast recovery diodes, reference should be made to their data manual or specification sheet. Understanding the standard performance parameters provided by manufacturers can help to correctly interpret test results.

ESD (electrostatic discharge) prevention: Fast recovery diodes, like other semiconductor devices, are sensitive to static electricity. When operating and testing these diodes, appropriate ESD precautions should be taken, such as using anti-static wristbands and anti-static workbenches.

Comprehensive evaluation: A single test result often cannot fully reflect the performance of the diode. Therefore, multiple methods such as visual inspection, forward voltage drop testing, and reverse leakage current testing should be combined to comprehensively evaluate the status of the diode.

Routine inspection of fast recovery diodes is a crucial step in ensuring the reliability of electronic devices. Through the above methods and precautions, FAE engineers can effectively evaluate the performance of fast recovery diodes, promptly identify and solve potential problems. However, given the particularity of fast recovery diodes, more advanced testing equipment and techniques may be required in specific situations.

Previous: Classification, Structure, and Principle of MOSFET